![]()

Instruments for Rheology testing

![]()

MooneyCheck – Drive

Mooney Viscometer controlled by Personal Computer.

Key Features

• Performance of Viscosity, Pre-curing (Scorch) and Stress relaxation tests.

• Test chamber and rotor in accordance with international standards.

• Independent PID temperature controllers with a resolution of 0.1 ° C.

• Touch screen for device control.

• Calibrated internal weight for automatic calibration.

• Pneumatic rotor discharge system.

• Easily accessible test chamber with transparent security panel and safety lock.

• Full license of Mooneycheck_10 software optimized for barcode sample identification.

• Complete license of Datagest_10 software for complete management of the Gibitre SQL Database.

Accessories

• Volumetric die cutter.

• Polyamide or Polyester Film to protect molds during testing.

![]()

Instruments for Force-Displacement testing

![]()

Automatic Hardness testers

![]()

Micro-IRHD hardness testers with Laser Centring

![]()

Manual Shore Tester

|

Manual Digital Hardness Tester Portable instrument for the measurement of shore Hardness consisting of Shore testing unit (Shore A, D, A0, 00) and battery powered digital console. |

|

Software Control system for Hardness Units Gibitre has developed specific software for the control of hardness units.The program is compatible with Windows 7 and 8(32 and 64 bits). |

|

Official Calibration of Hardness Units Gibitre Instruments is official ACCREDIA Calibration Laboratory n° 182 according to ISO 17025 standard and provides calibration service for Shore and IRHD hardness testers. |

![]()

Samples for Hardness Verification

![]()

|

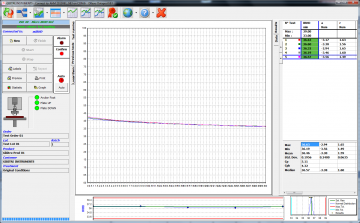

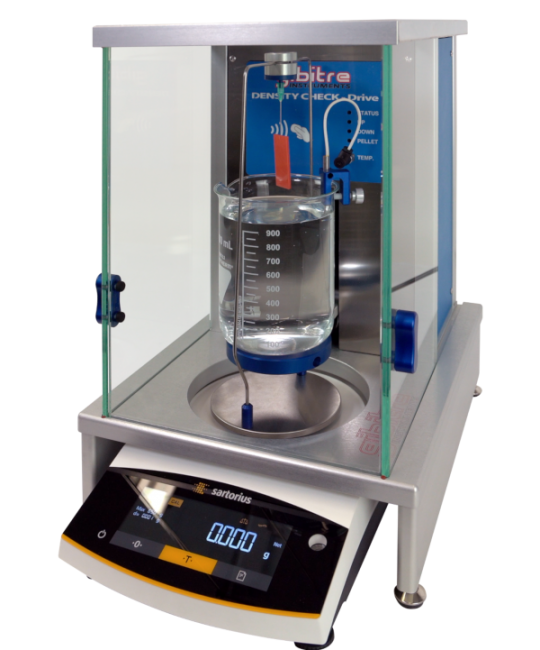

Density Control – PC – PC controlled Electronic Densimeter for automatic use of density of compact and cellular (non-absorbent) materials,% Mass Change (DM) and Volume Change (DV) |

Performing a test is quick and works:

• The sample has a sample holder.

• Attach the sample holder to the magnetic clamp.

• Let’s start.

The device automatically records the weight of the detail, moves upward with a reference fluid to measure the detail and density. It eventually moves to the starting position for the next test.

Key Features

• First brand scale in 0.001 g soluble class (optionally 0.0001 g) first class scale.

• Magnetic sample holder for fast sample change.

• Reading the temperature of the reference liquid for the thermal sensor and automatic density adjustment.

• Motor controlled lifting system that moves the beaker up and down under automatic operation of the test.

• Automatic calculation of Density and% Mass Change and% Volume Change after aging of samples.

• It is analyzed by examining and examining the tolerances of the results.

• Storage of data and curves in the standard Gibitre SQL database.

• Complete license of Datagest_10 data for the necessary management of the Gibitre SQL Database.

accessories

Special sample holders are available for different product types.

![]()

|

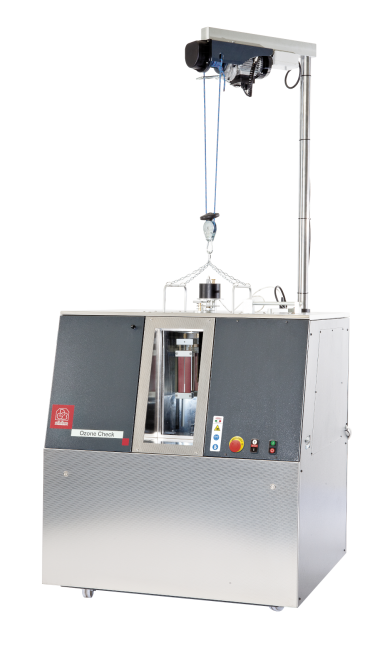

Ozone Check – UV – Electronic Ozone Tester for the evaluation of the ozone resistance of rubber samples. |

Gibitre Ozone control is a complete ozone cabinet for measuring the resistance of rubber samples or technical materials to breakage in static or dynamic tensile stresses. The device allows you to set test conditions to comply with international standard methods.

Key Features

Automatic regulation of Ozone Concentration, Temperature, Air Flow and Relative Humidity (optional)

• Performance of Static or Dynamic tests.

• UV absorption Ozone detector.

• Stainless steel cylindrical test chamber for homogeneous ozone distribution.

• Ozone production and reduction in closed circuit (no exhaust discharge required)

• CE labeling.

Software

Controllable using Gibitre-OzoneCheck software: adjusting test conditions, storing results, taking test curves and sample images into SQL database, automatic test stop and test suspension control, managing independent sample groups, recovery after power failure.

accessories

• Supporting static and dynamic testing of standard samples, technical parts and rubber hoses.

![]()

Low Temperature Check

Automatic instrument for the determination for both TR TEST and BRITTLENESS POINT

The structure of the Low Temperature Control is designed to allow arrangements for TR and Fragility point tests and includes the common parts required for the low temperature test: stainless steel tank, temperature controllers, mixer, electronic card, safety devices and CE Labeling.

Cooling systems are available: nitrogen tank or cooling unit. Cooling is automatically controlled by the device according to the set temperature of the test procedure used.

The arrangement for the TR test includes:

• Sample holder for simultaneous testing of 6 samples.

• Temperature Drawing Software that allows: enter the identification of samples (up to 3 products), cool and condition samples, start testing, draw retraction curves for each sample, calculate test results, check tolerance limits, record results and curves.

The Fragility Point test for editing includes:

• Pneumatically driven striker in accordance with international standards.

• Sample holder for 10 samples.

• Fragility Point Software that allows: Cooling and conditioning of samples, activating the striker, recording the temperature and the speed of the striker, allowing the user to reach the test results after visual inspection, Calculating and recording the Fragility Point Temperature.

![]()

![]()

![]()

Schob type Rebound Tester fitted with touch-screen Display system for the calculation of the resilience of elastomers with hardness between 30 and 85 irhd.

The touch screen provides:

– View the results of the 5 tests performed on the sample.

– Calculate the average and standard deviation of the results.

– Calibrate the angle reading of the device.

– Export data.

Sample holder is supplied with a tool for easy insertion and removal of the sample, according to ISO 4662 and ASTM D 7121 standards.

![]()

Block Oven Aging Check – Thermally regulated Block for the performance of aging tests in temperatures up to 250 ° C, fluids in air and elastomeric materials.

|

Thermally regulated block for performance of aging tests at temperatures up to 250 ° C, air and liquids of elastomeric materials. Technicial Specifications |

The device is equipped with:

• 4 calibrated perforated aluminum blocks designed to accommodate 4 glass test tubes.

• Thermally insulated stainless steel body and outer shelf for easy sample preparation.

• Heating resistances.

• PT 100 thermal probe for temperature measurement.

• PID Thermoregulator.

• Timer to set the heating time by automatically switching off the heater at the end of the set time.

• Safety switch to prevent overheating.

Accessories

• Glass tubes of 38 mm diameter and 300 mm length.

• Water cooled backflow capacitor.

![]()

![]()

Flammability Check – Stainless Steel Cabinet to perform flammability tests of plastic materials, foams and rubbers according to UL 94, ASTM D 635 and equivalents.

![]()

![]()

Laboratory Press – Laboratory presses for clamping plates and samples for laboratory tests.

Key Features

• 4 column (60 mm diameter) mechanical structure and self-lubricating bush driven slide plate.

• 250×250 mm chrome plated steel plates in 40 mm thickness.

• Flat heating elements specially designed to ensure an even temperature distribution over the plate surface.

• Closed molding area for easy smoke aspiration.

• Safety locked security doors.

• CE Labeling.

accessories

• Automatic Press Control with Touch Screen: Allows adjustment of the molding cycle.

• Cooling system: controls the cooling of the plates for molding thermoplastic products.

• Closing Force Control: Provides continuous regulation of the closing force to be adjusted for each stage of the molding cycle.

• Press Control Software: Allows the molding condition to be recorded and stored for each molding cycle.

• Plates and molds to produce different types of samples according to international standards.

![]()

Laboratory Splitting machine for the preparation of test samples starting from finished rubber products

Key Features

• Maximum working width 300 mm.

• Adjustable cutting thickness. (0.5 to 8 mm)

• Digital display control panel of cutting thickness adjusted with 0.01 mm resolution.

• Motor driven upper and lower steel feed rollers at adjustable speed (0.9 / 1.8 / 2.8 m / min).

• Micrometric driven sharpening device.

• Integrated lubrication on both the top and bottom surface of the blade.

• Manual Micrometric blade positioning and waste compensate for blade consumption.

• Optical group to control chamfer position and symmetry.

• CE Labeling.

Accessories

• Removable suction unit.

• Lubricating fluid.

![]()